Understanding the Process of EV Charger Installation

Introduction and Outline

Electric vehicles are reshaping how we think about getting from A to B, and charging stations are the practical bridges that make this new mobility work. The installation of an EV charger is not just another home upgrade or commercial project; it’s a small infrastructure build that touches safety, power availability, future expansion, and budget. As more drivers switch to electric, demand for reliable charging has accelerated, pushing homeowners, property managers, and communities to plan smartly rather than reactively. The good news: with a clear process, evidence-based choices, and a little foresight, installation is manageable and can be tailored to different sites and use cases.

This article focuses on the practical path from idea to energized charger. To make it usable, here is the roadmap we’ll follow before diving into each part in detail:

– Home EV charger installation, step-by-step: assessment, power levels, wiring, safety, and costs.

– Public and commercial charging projects: site selection, utility coordination, civil works, and operations.

– Power and hardware fundamentals: AC vs. DC, charging curves, connector types, and what shapes actual speed.

– Permitting, incentives, and total cost of ownership: timelines, paperwork, and realistic budget planning.

– Future-proofing and reliability: smart load management, resilience, maintenance, and data-informed decisions.

Throughout, you’ll see comparisons that matter in the real world, such as Level 1 vs. Level 2 at home, or curbside AC vs. high-power DC for highway sites. We’ll translate technical terms into practical outcomes: what a 40-amp circuit means for daily commuting, how trench length shifts installation cost, and why charging speed tapers as a battery fills. Expect a few field-tested rules of thumb, options for different building types, and guidance to avoid common pitfalls like undersized conduit or overlooked permitting steps. Think of this as a guidebook for building a dependable “fueling lane” where you live or work.

Home EV Charger Installation: A Step-by-Step Path

Installing a home EV charger starts with a simple question: how much charging do you really need each day? Many drivers average 20–40 miles daily, which a Level 2 charger can comfortably cover overnight. Begin with an electrical assessment to understand available capacity. An electrician will review service size (often 100–200 amps in many homes), panel space, main breaker rating, and the presence of other large loads such as HVAC, electric ranges, or electric water heaters. A load calculation ensures the new circuit stays within code requirements and continuous load limits.

Next, choose the power level and circuit. Level 1 (120 V) is slow but reliable; it can add roughly 3–5 miles of range per hour and may be sufficient for low-mileage drivers. Level 2 (usually 240 V at 30–60 amps) is the sweet spot for most households, adding approximately 25–40 miles per hour depending on vehicle acceptance rate and charger output. The circuit amp rating, conductor size, and breaker selection should align with the charger’s continuous load and manufacturer specs. While some vehicles accept higher AC rates, the actual charge speed is capped by the lower of the charger output and the onboard vehicle charger capacity.

Placement matters more than it seems. A wall near the parking space minimizes cable clutter and keeps conduit runs short, reducing cost. Consider reach to both front and rear charge ports, and plan for future vehicles that might place the inlet in a different location. If the garage is detached or the parking spot is outdoors, weatherproof enclosures and appropriately rated conduit and fittings are needed. An outdoor-rated unit and properly sealed penetrations protect against moisture and corrosion.

Permitting and inspection are essential for safety and insurance compliance. Many areas require a permit for a new 240 V circuit. Timelines vary, but a typical home project can move from estimate to activation in 1–3 weeks if capacity is available, extending to 3–8 weeks when panel upgrades or service increases are required. Cost varies by site conditions, but a ballpark guide helps:

– Level 2 charger hardware: roughly a few hundred to over a thousand in local currency, depending on features.

– Standard installation: often in the several-hundred to low-thousands range when the panel is near the parking spot.

– Panel upgrade or long conduit runs: can add significant cost, sometimes in the low-thousands to several-thousands depending on distance and complexity.

Commissioning closes the loop. After installation, test the unit at various current settings, confirm ground fault protection, verify cable management, and ensure the vehicle charges as expected. If the charger includes smart features, connect it to Wi‑Fi or cellular service and set power limits or schedules to match off-peak rates. With a thoughtful plan, a home charger turns the daily commute into a routine top-up, much like plugging in a phone overnight.

Public and Commercial Charging: From Site to Switch-On

Public and commercial charging projects resemble compact utility builds, with tasks that span site selection, power studies, civil works, permitting, procurement, and ongoing operations. Start by matching charging types to the location’s use case. Retail and restaurants benefit from Level 2 where dwell time is 1–3 hours. Travel corridors, logistics hubs, and fleet depots often justify DC fast charging to support quick turnarounds. Mixed sites can combine AC for longer stays and DC for rapid needs, using smart load management to share capacity.

Power availability is the cornerstone. Conduct a site load analysis, review existing service, and request a utility capacity check. When available capacity is tight, options include service upgrades, new transformers, or phased builds that add chargers over time. Long-term planning matters because trenching and conduit are major cost drivers; it’s often efficient to oversize conduit and pull boxes for future cables even if phase one installs only a few pedestals. Consider cable routing that avoids tree roots or hardscape demolition, and choose parking spaces with good sightlines, lighting, and accessible pathways.

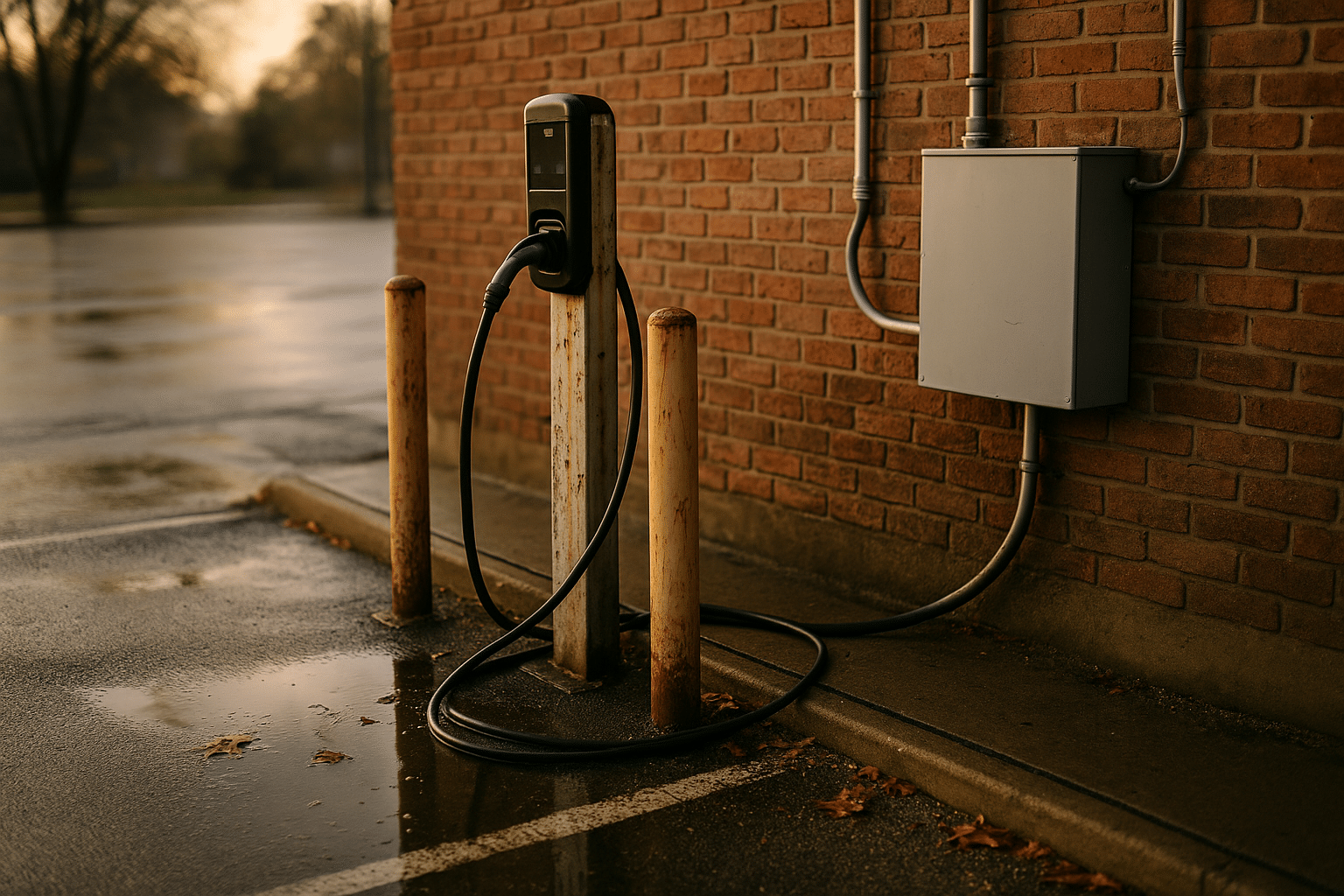

Civil and electrical scopes typically include saw-cutting asphalt or concrete, trenching, installing conduit and wire, constructing concrete pads, mounting pedestals or cabinets, and integrating switchgear and protective devices. Drainage and water management are not afterthoughts: standing water shortens equipment life and can create hazards. Signage helps drivers find chargers quickly, and clear pavement markings prevent ICEing (non-EV vehicles blocking spaces). Compliance with accessibility requirements, appropriate mounting heights, and adequate maneuvering space ensures inclusive use.

Networking and payment determine user experience. Reliable cellular or hardwired connectivity enables real-time status, pricing, and remote troubleshooting. Payment options should be simple and consistent, supporting tap-to-pay and app-based sessions where permitted. Track uptime rigorously; leading programs target high availability percentages, and that requires spare parts, preventive maintenance, and rapid response to faults. Data from sessions—start times, durations, power delivered—feeds capacity planning and informs when to add circuits or rebalance loads.

Budgeting for commercial sites depends heavily on scope. DC fast charging hardware can be a major line item, and installation costs can rival equipment costs when utility upgrades or long trenching runs are needed. To control spend, bundle work: coordinate utility service, civil, and electrical trades in one schedule; order materials early; and design for modular expansion. A well-run project reaches commissioning with thorough testing: insulation resistance checks, torque verification, communication validation, and pilot charging sessions with multiple vehicles to confirm compatibility and consistent throughput.

Power, Hardware, and Real-World Charging Speeds

Behind every smooth charging session is a balance among circuit capacity, charger output, vehicle acceptance rate, and battery chemistry. AC charging (Level 1 and Level 2) relies on the vehicle’s onboard charger to convert AC to DC, so the maximum rate is limited by the vehicle hardware even if the wall unit can provide more. DC fast charging bypasses the onboard charger and delivers DC directly to the battery, enabling higher power levels when the vehicle and battery temperature allow.

Typical power and performance ranges help set expectations:

– Level 1 (about 1–1.9 kW): adds roughly 3–5 miles of range per hour; useful for low daily mileage or workplace trickle charging.

– Level 2 (often 6–12 kW): can add around 25–40 miles per hour, ideal for overnight at home or multi-hour public stops.

– DC fast (commonly 50–350 kW): can add substantial range in 20–30 minutes on compatible vehicles, with speeds tapering as the battery approaches higher states of charge.

Why does speed vary so much? Batteries accept power fastest when they are warm and at moderate state of charge. As the pack fills, the charging curve tapers to protect longevity—think of it like gently topping off a water tank to avoid overflow. Cold weather slows charging because the pack needs to warm before it can safely ingest high power. Some vehicles precondition the battery on the way to a fast charger, but if not, the first minutes may be slower in winter until temperatures rise.

Hardware features influence outcomes. Cable gauge and length affect resistive losses and handling, while robust contactors and thermal management improve reliability during high-load sessions. Smart load balancing allows multiple chargers on a single feeder to share power dynamically, increasing site utilization without oversizing service. Connector types differ by region, and mixed-connector sites can serve a wider range of vehicles; verify regional requirements before ordering equipment. For multi-unit housing, wall-mounted units with shared load control reduce common-area electrical upgrades and keep tenant billing straightforward.

Safety is non-negotiable. Proper overcurrent protection, ground fault detection, clear labeling, and durable enclosures prevent hazards and minimize downtime. Use appropriately rated conductors and terminations, tighten to specified torque values, and protect cables from abrasion or vehicle impact. With the right pairing of power, hardware, and site design, drivers experience predictable charging, and operators gain dependable throughput without surprise utility bills.

Permitting, Incentives, Costs, and Budget Clarity

Permitting is the paper backbone of a solid installation. At minimum, expect an electrical permit for new circuits, with plan sets showing conduit routes, conductor sizes, breaker ratings, and equipment mounting details. For public sites, additional reviews may include zoning, signage, parking layout, and in some cases stormwater or traffic considerations. Early conversations with the authority having jurisdiction reduce resubmittals and keep schedules intact.

In many regions, incentives can materially change the budget. Programs may offer rebates for hardware, make-ready construction, or both, sometimes covering a significant share when projects meet published criteria such as uptime targets or open access. Utility programs might fund service extensions or panel upgrades to encourage transportation electrification. To capture these benefits, assemble documentation early: load calculations, equipment cut sheets, site plans, and commissioning procedures. Keep in mind that incentives often require pre-approval; starting work before approval can disqualify a project.

Costs vary, but a structured estimate prevents surprises. For homes, a typical Level 2 install with a short conduit run and available panel space often lands in the lower-thousands range (including hardware), while panel or service upgrades can lift totals to several-thousands. For public Level 2, per-port costs move higher due to trenching, bollards, signage, networking, and more robust enclosures. DC fast charging commands the largest budgets: hardware can range widely by power rating, and installation may involve pads, switchgear, long feeders, and utility upgrades. Soft costs—design, permitting, inspection scheduling, and commissioning—add up and should be forecast alongside construction.

Practical budgeting tips help stabilize outcomes:

– Design for expansion: oversize conduit and leave pull strings for future cables.

– Shorten trench runs where possible: place equipment near existing power to cut material and labor costs.

– Standardize equipment across sites to simplify spare parts and maintenance.

– Align construction with incentive milestones to avoid missing funding windows.

Finally, commissioning and documentation are your warranty against doubt. Record as-built drawings, torque logs, insulation resistance test results, and network configurations. Provide owners with a quick-start checklist and a maintenance calendar. Clear records speed troubleshooting months later and are often required for incentive verification and warranty support.

Future-Proofing, Reliability, and Ongoing Operations

Chargers are long-lived assets, and thoughtful operations turn them from equipment into dependable service. Start with uptime goals and work backward: define preventive maintenance intervals, response times for faults, and escalation paths for issues that require parts replacement. Stock commonly replaced items—cable holsters, fuses, contactors, and labels—and keep a small cache on hand for critical sites. Remote diagnostics can solve many problems without a truck roll, but only if networking is robust and securely configured.

Smart load management is a practical way to stretch capacity as usage grows. By assigning power priorities or dynamic setpoints, multiple ports can share a feeder while protecting the main service. This is especially valuable in multifamily buildings and workplace lots where usage peaks at predictable times. Over time, usage data helps right-size future additions: charts of session overlap, average dwell time, and seasonal trends reveal whether to add more Level 2 ports, a pair of DC fast units, or simply upgrade feeder capacity.

Resilience matters. Weather, grid disturbances, and construction nearby can disrupt service. Where budgets allow, consider on-site storage to shave demand peaks or ride through short outages, and pair with solar to offset daytime loads. Even without large additions, small design choices—raised pedestals above grade, sealed conduit entries, good drainage, UV-resistant cable jackets—extend life and reduce failures. Security lighting and clear sightlines deter vandalism and make sites more welcoming after dark.

Policy and standards continue to evolve, and staying adaptable pays dividends. Choose equipment that supports over-the-air updates and open communication protocols to avoid lock-in and enable future integrations. For public sites, transparent pricing and clear session receipts build trust, while flexible tariffs encourage off-peak use that benefits both drivers and the grid. For fleets, coordinated scheduling with route planning keeps vehicles topped up without straining infrastructure.

To keep things running smoothly, formalize a simple, repeatable playbook:

– Quarterly inspections: check cable wear, connector cleanliness, enclosure seals, and signage condition.

– Semiannual electrical checks: verify torque on terminations, test ground fault protection, and review breaker health.

– Annual performance review: analyze uptime, session growth, cost per kWh delivered, and plan capacity changes.

With this operational backbone, charging stations remain reliable community assets. Drivers get predictable fueling, property owners see steady utilization, and the broader transportation network gains a sturdy, scalable foundation for the continued rise of electric vehicles.

Conclusion: Turning Plans into Plug-Ins

Whether you’re a homeowner, facility manager, or developer, the path to a dependable EV charger follows the same logic: assess capacity, match power to use cases, build to code, and plan for tomorrow. Home installations transform daily driving into convenient overnight refueling, while well-sited public stations keep trips flowing and fleets on schedule. By budgeting realistically, leveraging incentives, and committing to maintenance, you create charging that’s reliable, safe, and ready to grow. Start with a clear outline, and the rest clicks into place—one circuit, conduit run, and energized port at a time.