Essential Guide to Installing a Home Hot Tub

A home hot tub can feel like a private retreat, but the difference between a smooth project and a frustrating one comes down to planning, safe installation, thoughtful plumbing, and steady maintenance. This guide breaks the process into clear stages, highlights code and safety touchpoints, and uses real-world numbers so you can estimate budgets and timelines. Whether you’re picturing a compact plug‑in spa on a patio or a larger hardwired unit on a reinforced deck, the principles here help you build with confidence and enjoy water that’s comfortable, clean, and reliable.

Article Outline and Project Roadmap

Before lifting a single panel or ordering fittings, map the project. A written outline turns a vague idea into a sequence you can schedule, price, and inspect. Think of it as your build script: the who, what, when, and where of a hot tub install. In this section, we provide a high-level roadmap and explain why each milestone matters, including permitting, load calculations, water management plans, and maintenance routines that keep operating costs stable over the long term.

Suggested outline with purpose and deliverables:

– Site Selection and Base: Choose location, assess structural capacity, manage drainage, and plan delivery path. Target deliverables: base type chosen (slab, pavers, or deck), slope and runoff plan, access verification.

– Electrical Plan: Determine 120 V versus 240 V requirements, breaker size, GFCI protection, and disconnect placement. Target deliverables: single-line diagram, permit approval, scheduled inspection.

– Plumbing and Water Management: Decide on fill and drain methods, hose bib placement, backflow prevention, and wastewater handling. Target deliverables: parts list (valves, unions, hose), freeze-protection approach if needed.

– Delivery and Set: Confirm equipment path widths (generally 36–42 in minimum), turning radius, and temporary ground protection. Target deliverables: crew plan, weather window, staging area.

– Commissioning and Maintenance: Water balance, sanitation method, filter routine, and seasonal procedures. Target deliverables: log sheet, test kit, replacement filter on hand.

Budget and time anchors reduce surprises. Typical hardwired tubs draw 30–50 A at 240 V and weigh 3,500–5,500 lb when filled, so base and electrical are major cost drivers. A compact slab (4–6 in, reinforced) may run a few hundred to a few thousand dollars depending on soil prep; electrical work varies widely based on panel capacity and run length. Timewise, many projects take 2–6 weeks from first permit to first soak, and weather can stretch that. Assign responsibilities early—who handles base prep, who pulls permits, who coordinates inspections—to prevent last‑minute scrambles.

Finally, document decisions. A simple folder with the wiring diagram, breaker rating, base drawings, and water‑care schedule becomes your owner’s manual. When you return in six months to adjust chemistry, you won’t be guessing; you’ll be following your own plan.

Installation: Site Selection, Base Prep, and Delivery Logistics

A great hot tub experience starts with where you set it. Location influences noise, privacy, wind exposure (heat loss), and maintenance access. Favor a spot with short electrical runs, nearby water access, and room to remove side panels for service. Many installers prefer 18–24 in of clear space on at least one side for equipment access. If placing near a doorway, think splash zones and wet‑footing safety—textured pavers and non‑slip mats minimize slips.

Structural support is non‑negotiable. A filled spa often exceeds two tons; some models push past 5,000 lb. For ground installs, three common bases are:

– Concrete slab: 4–6 in, steel reinforced, compacted subgrade; durable and flat.

– Interlocking pavers: cost‑effective if subbase is well compacted; allow drainage through joints.

– Gravel with prefabricated pad: fast to install; requires careful leveling and edge restraint.

Deck installs demand special attention. Residential decks are often designed for 40–60 psf live load, while a hot tub can impose 90–150+ psf depending on size and footprint. If placing on a deck, involve a qualified professional to verify joist sizing, beam spans, post footings, and connectors. Reinforcement—sistered joists, added beams, or extra posts—may be needed. As a rule of thumb, the tub should sit on framing that distributes weight to posts or footings, not only to deck boards.

Drainage and slope protect both structure and sanitation. A mild slope (about 1–2% away from the tub) sheds rainwater and splash. Avoid low spots where water puddles around equipment doors. If winds are common in your area, a windbreak like a fence section or shrub line can reduce evaporative heat loss by double‑digit percentages, making the cover’s job easier.

Plan the delivery path with tape measure honesty. Many shells are 32–40 in deep and travel on their side. Measure gate widths, fence corners, and overhead obstructions. For tight sites, temporary fence panel removal or a small crane may be more cost‑effective than risky maneuvering. Protect lawns with plywood sheets if the ground is soft. Delivery day checklist:

– Clear path width and height verified end‑to‑end.

– Base level within manufacturer tolerance (often ±1/8 in per 8 ft).

– Weather window checked; avoid setting in heavy rain or on soggy ground.

– Helpers assigned for guiding and spotting.

Once the tub is in place, confirm it is level and stable before connecting anything. A carpenter’s level across multiple points helps catch subtle dips; shim only under the base, never under the shell. This careful pacing early on pays back with quieter pumps, better waterline appearance, and less strain on plumbing unions.

Installation: Electrical Requirements, Safety, and Efficiency

Hot tubs are high‑load appliances, and electrical safety is paramount. Many units are 240 V hardwired on a dedicated 50 A GFCI circuit, though some compact models run on 120 V, 15–20 A plug‑in circuits with reduced heater output. A dedicated circuit with properly sized copper conductors, an outdoor‑rated disconnect within sight, and bonding in accordance with code are typical requirements. Always follow local regulations and schedule inspections where required.

Key considerations and practical comparisons:

– 120 V (plug‑in): easier setup and lower upfront electrical work; slower heating and limited simultaneous pump/heater operation.

– 240 V (hardwired): faster heating, more robust performance in cold weather; requires permit, GFCI breaker, larger conductors, and professional installation.

– GFCI protection: essential for personal safety; typically at the breaker or within the outdoor disconnect.

– Conduit choice: PVC Schedule 40 is common underground; metallic conduit (EMT) may be used above‑ground where allowed. Burial depth and fittings must match code.

Distance matters. Longer wire runs increase voltage drop; keeping the disconnect close (within code limits) and choosing proper conductor gauge protect equipment performance. For planning: a 50 A, 240 V circuit often uses 6 AWG copper conductors, though exact sizing depends on run length and code. Bonding any nearby metal within the specified perimeter reduces stray voltage risk.

Indoor installs require special ventilation. Warm, moist air raises humidity and can condense on windows and framing. A dedicated exhaust strategy, vapor‑retarder surfaces, and corrosion‑resistant fasteners help avoid damage. Floor drains or secondary containment trays can catch overflows and simplify maintenance.

Energy and operating cost expectations help set a realistic budget. With a quality cover and wind protection, many owners report 6–12 kWh per day depending on climate and usage. At $0.15 per kWh, that’s roughly $27–$54 per month, rising in colder, windier locations or with frequent long soaks. Efficiency tips that actually move the needle:

– Close the cover promptly; heat loss spikes with exposed surface area.

– Use a windbreak; even a modest fence can cut heat loss meaningfully.

– Keep filters clean; clogged cartridges force longer pump cycles.

– Consider a slightly lower standby setpoint; dropping 2–3°F off-peak can trim consumption without comfort penalty.

Finally, label the disconnect and keep the wiring diagram in your project folder. In an emergency or during service, clear identification saves time and enhances safety.

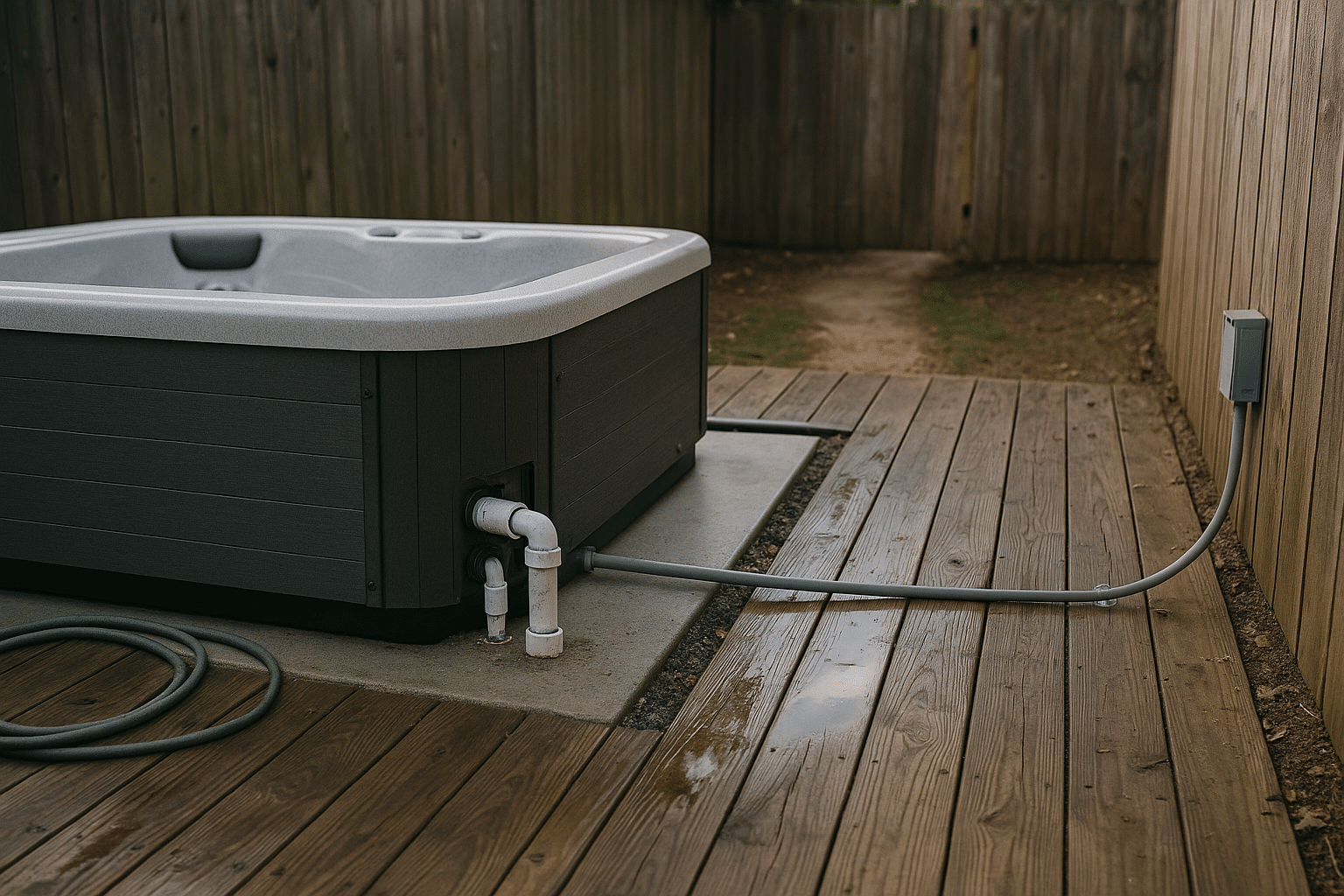

Plumbing: Water Supply, Drainage, and Leak‑Free Connections

Most portable hot tubs arrive with internal plumbing complete, but you still decide how to fill, how to drain, and how to manage water around the site. A nearby hose bib with good pressure makes filling straightforward; a typical 350‑gallon spa can take 60–90 minutes to fill with a standard garden hose. For drainage, plan where water will go before the first changeout. Many homeowners direct drain water across landscaping or to a gravel bed, ensuring it doesn’t flow onto a neighbor’s property or into storm drains where restricted. Always verify local rules for discharge.

External plumbing choices come up when you add valves, unions, or winterization fittings. Flexible PVC is forgiving on slight misalignments and vibration; rigid Schedule 40 offers crisp alignment and strong joints. Whichever you choose, primer and cement technique matters: clean, dry, square cuts; even primer; quarter‑turn push during assembly; and full cure time before pressurizing. Common failure points include poorly supported unions near pumps and heaters, and barb fittings with under‑clamped hoses. Adding simple supports and double stainless steel clamps on soft hoses reduces nuisance leaks.

Hydraulics in plain language: pumps push water through filters and heaters to jets, and every foot of pipe, elbow, and small filter pleat adds resistance. Typical circulation rates are 30–60 GPM, and pushing too much flow through a fine‑micron filter increases head loss, raising energy use and pump noise. That’s why many systems separate a low‑flow circulation pump from high‑flow jet pumps. If you’re retrofitting or troubleshooting, look for smooth sweeps over sharp 90s where possible, minimize unnecessary fittings, and keep suction lines unobstructed.

Air, check valves, and anti‑siphon details deserve attention. Jet lines often entrain air for a livelier feel; anti‑siphon loops above waterline help prevent backflow when the pump stops. Check valves on ozone or air injection lines keep water out of delicate components. For cold climates, consider drain tees or union points at low spots to ease winterization. A basic sequence for leak checks:

– Dry‑fit and mark alignment, then glue with quarter‑turn pressure.

– Allow full cure (temperature affects time).

– Fill incrementally, inspecting every union and joint with a dry towel.

– Run low‑speed pumps first; then test high flow.

Backflow and cross‑connection safety is simple but important. Keep fill hoses from submerging below the waterline, or use a vacuum breaker on the hose bib if your jurisdiction requires it. Never tie spa drains directly into sanitary lines without permits and proper traps; it’s cleaner and often simpler to use gravity drains to grade or a sump pump to a safe discharge point.

In short, thoughtful plumbing is quiet, dry, and accessible. If you can reach unions without performing gymnastics, future you will be grateful.

Maintenance and Long‑Term Care

Water care is where comfort and health meet. Whether you choose chlorine, bromine, or a supplemental system such as ozone or UV, the targets are consistent: clear water, stable pH, and sanitized surfaces. Core ranges most homeowners use successfully include: free chlorine 1–3 ppm (or bromine 3–5 ppm), pH 7.2–7.8, total alkalinity 80–120 ppm, and calcium hardness 150–250 ppm for acrylic shells. Test strips are quick; liquid kits offer finer resolution. Log results so you can see trends and correct gently rather than swinging chemistry with big doses.

Routine schedule that keeps problems small:

– After each use: run the jets with the cover open a few minutes to vent, then confirm sanitizer level.

– Weekly: test and balance pH/alkalinity; oxidize (“shock”) to remove organics; wipe waterline to prevent scum build‑up.

– Monthly: clean filters; a simple hose rinse weekly plus a deeper soak in filter cleaner monthly maintains flow.

– Quarterly (typical): drain and refill, or use a rule of thumb—water replacement interval (days) ≈ (Spa volume in gallons ÷ 3) ÷ average daily bather load. Heavy use shortens the interval; light use extends it.

Energy care matters, too. Keep the cover in good shape; a waterlogged cover is heavy and leaks heat. Small adjustments pay off: lowering standby temperature by 2–3°F, blocking prevailing winds, and cleaning filters can shave meaningful kWh. In winter, consistency beats big temperature swings; the tub works harder to reheat large drops than to maintain a steady setpoint.

Troubleshooting without drama:

– Cloudy water: check filtration first, then sanitizer; increase circulation time and shock if needed.

– Foam: often cosmetics or detergents; ask guests to rinse off; use a defoamer sparingly and improve water changes.

– Odors: low sanitizer or biofilm; deep clean filters and perform a thorough shock before refilling if persistent.

Conclusion for Homeowners

A hot tub rewards steady, modest effort. By choosing a solid base, wiring safely, planning fill and drain paths, and following a simple maintenance rhythm, you convert day‑one excitement into year‑round relaxation. Keep a small toolkit—a test kit, spare filter, sanitizer, and a soft brush—and note readings in your log. With a clear plan and a few good habits, your quiet evening soak becomes a lasting routine rather than a weekend project on repeat.