Understanding the Benefits of Impact Hurricane Windows

Outline:

1) Why impact-resistant hurricane windows matter for safety, comfort, and daily living.

2) How hurricanes damage windows: pressure, debris, and code expectations.

3) What makes an impact-resistant window work: laminated glass, frames, ratings, and energy performance.

4) Windows vs shutters vs films vs plywood: costs, convenience, and aesthetics.

5) Buying, installation, maintenance, and a practical conclusion for homeowners.

Why Impact-Resistant Hurricane Windows Matter

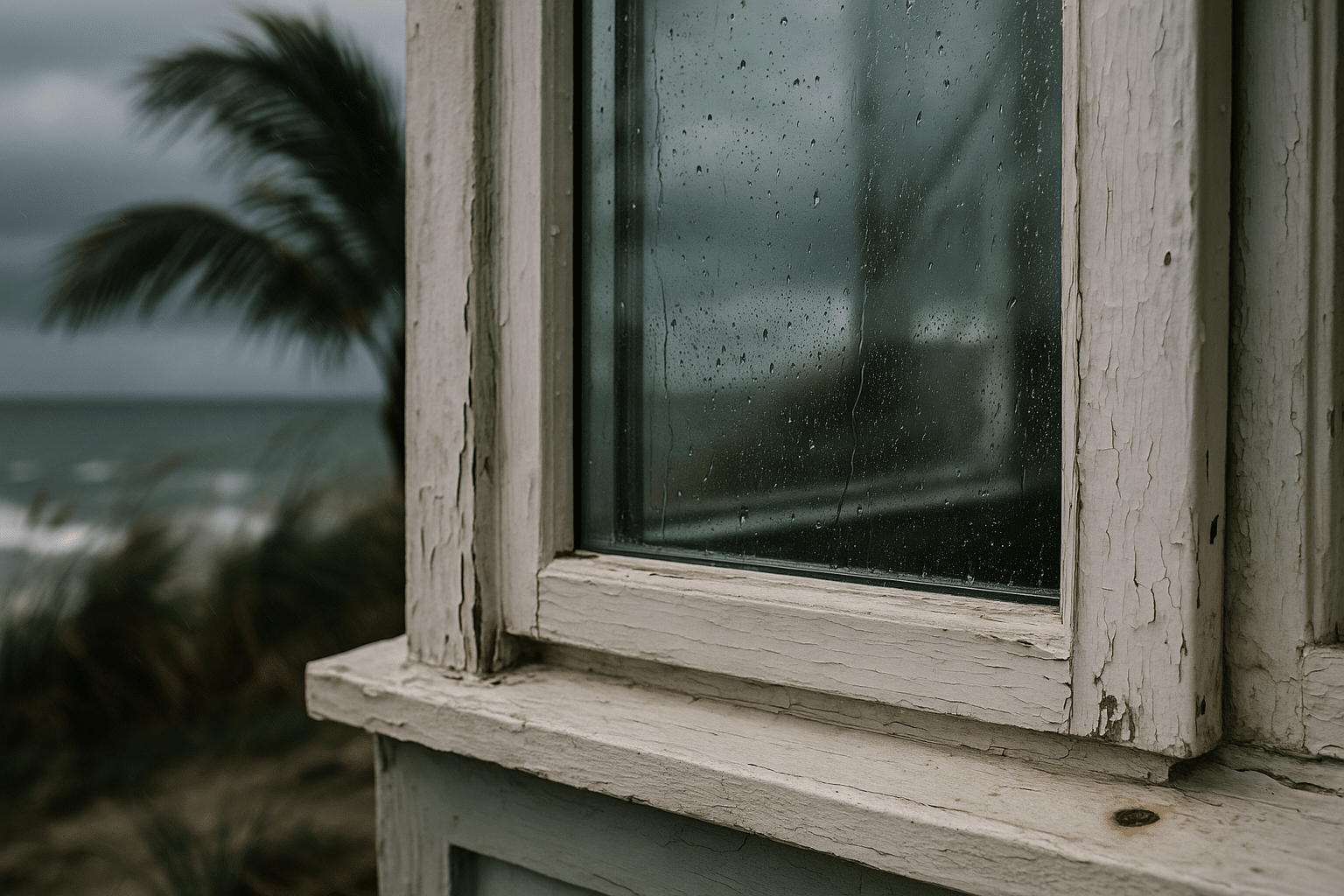

Every coastal homeowner knows the ritual of watching weather maps as tropical systems spin toward shore, but far fewer consider how a single broken pane can escalate into a catastrophic loss. When a window fails during a storm, it is not just the rain and wind that enter; the home’s interior rapidly pressurizes. That inward push at the weakest point can force roof decking upward and peel cladding away, turning one cracked lite into structural damage, water intrusion, and weeks of disruption. Impact-resistant hurricane windows are designed to interrupt that cascade. They combine laminated glass and reinforced framing to resist flying debris and the repeated pressure swings that typify a long storm. Unlike temporary coverings, they safeguard the building envelope 24/7, keeping rooms bright, reducing noise, and adding day-to-day comfort the rest of the year.

The appeal is both practical and personal. Families gain a quieter home because laminated interlayers dampen sound; valuables are shielded from fade thanks to high UV filtering; and the inconvenience of last-minute boarding is replaced by calm preparation. There is also a resilience advantage that extends beyond any one storm. Well-selected units are tested to withstand a heavy lumber projectile hitting the glass at highway speeds and then endure thousands of alternating suction and pressure cycles. That combination matters because real storms deliver not only one hard hit but many hours of turbulent loading. In neighborhoods where outages and access restrictions are common, having protection that is always in place can be the difference between returning to a dry, intact living room and confronting soggy drywall and warped floors.

There are day-to-day payoffs as well. Modern glazing options can improve thermal performance, which helps reduce hot spots and lowers cooling demand. For many households, the decision pairs safety with comfort and efficiency in a single upgrade. Typical motivations include:

– Year-round defense without deploying panels or devices

– Reduced exterior noise from traffic, boats, or aircraft

– Better solar control and UV reduction that protects finishes

– Peace of mind for second homes or properties managed from afar

Taken together, impact-resistant windows offer a balanced, durable path to a more secure and livable space, in fair weather and foul.

How Hurricanes Break Windows—and What Codes Expect

Hurricanes attack windows in two principal ways: high-velocity debris and fluctuating wind pressure. First, windborne objects—roof tiles, branches, bits of siding—become missiles that strike glass at speeds comparable to a passing car. A sharp impact can create cracks, but the real threat is penetration, which suddenly exposes the interior to driven rain and pressure. Second, storms apply pulsating loads as gusts surge and recede. That cycling is especially damaging, because tiny deflections accumulate; seals fatigue; and any initial damage can propagate. Engineers estimate wind pressure using dynamic equations that scale with the square of wind speed, which is why the jump from 90 to 120 miles per hour is not just 33 percent more intense—pressures roughly double. In short, both the short, sharp shock and the long grind matter.

Building codes in coastal regions acknowledge this reality by requiring two layers of performance: impact resistance to handle debris and cyclic pressure performance to endure the storm’s duration. Laboratory tests simulate a worst-case event by launching a 9‑pound two-by-four into the glazing at a set speed, then subjecting the window to thousands of positive and negative pressure pulses to mimic gusting. A unit passes when it prevents a breach; the glass may crack, but the interlayer must hold together, and the frame must remain anchored. In addition, design pressure ratings specify how much steady wind load a window can withstand without unacceptable deflection or leakage. Communities closest to shore often adopt higher thresholds, sometimes called high-velocity zones, while areas further inland require windborne-debris protection only in certain exposures.

Homeowners can translate this into practical action with a few steps:

– Check your mapped wind speed and exposure category through local authorities

– Confirm that chosen windows carry labeled ratings for impact and pressure cycling

– Ensure the installation method secures the frame to structure, not just sheathing

– Verify water management details such as sill pan flashing and drainage paths

Meeting the intent of the code is not simply about passing a lab test; it is about preserving life, property, and the ability to reoccupy the home quickly. Windows that resist both debris and prolonged suction/pressure help keep the building envelope intact, reducing secondary losses from water and mold long after the winds subside.

Inside an Impact-Resistant Window: Materials, Ratings, and Performance

The core of an impact-resistant window is laminated glass—two or more sheets bonded by a transparent polymer interlayer. When struck, the glass may fracture, but the fragments adhere to the interlayer, maintaining a barrier against rain and pressure. Interlayers vary: polyvinyl butyral offers clarity and sound damping, while ionoplast formulations add stiffness for demanding conditions. Thicknesses commonly range from roughly 0.030 to 0.090 inches, with thicker builds used for larger sizes or higher debris ratings. Many products pair the laminated pane with an insulated airspace and a second lite, improving energy performance by reducing conductive and radiant heat transfer.

Frames are equally important. Reinforced aluminum brings slim sightlines and durability; improved thermal breaks and glazing beads mitigate heat flow and condensation risk. Heavy vinyl frames use multi-chamber designs and steel or composite reinforcements to resist deflection while maintaining thermal efficiency. Fiberglass offers low expansion and high strength, which helps preserve seal integrity across seasons. Regardless of material, the goal is a stiff, well-anchored perimeter that transfers loads to the structure. Hardware—hinges, locks, rollers—must be corrosion resistant and robust, because operable units face repeated wind loads and salt-laden air in coastal climates.

Performance shows up as labels and numbers. Look for a clear impact rating, a design pressure or performance grade matching your site, and air and water infiltration metrics appropriate for your exposure. Energy values matter, too: a low U-factor helps with conductive heat loss, while a suitable solar heat gain coefficient balances glare control and daylight. Color-neutral low-emissivity coatings can cut cooling loads without turning interiors dim. Owners may also notice everyday perks: laminated glass can shave several decibels off outdoor noise, and most interlayers block a large share of UV—useful for protecting fabrics and flooring. In practice, impact-resistant windows earn their keep across the calendar:

– During storms by resisting debris and pressure cycling

– In summer by limiting solar heat gain and hot spots

– Year-round by softening street noise and filtering UV

That multi-benefit profile makes them a resilient upgrade rather than a single-purpose accessory.

Windows vs Shutters vs Films vs Plywood: A Practical Comparison

Owners weighing protection choices often juggle cost, convenience, and aesthetics. Impact-resistant windows are a permanent solution that requires no deployment, preserve curb appeal, and allow daylight during a storm. Installed costs vary by size, style, and glazing package, but many projects fall in the range of several hundred to over a thousand dollars per opening. By contrast, panel shutters made of metal or polycarbonate can be economical per square foot, yet they need storage and time to mount before every storm. Accordion and roll-down systems add convenience with higher upfront cost and ongoing maintenance of tracks and fasteners. Safety films are popular for hold-together benefits, but most do not satisfy debris-impact requirements for hurricane zones when used alone. Plywood is the budget fallback, but it is heavy, difficult to deploy under pressure, and only effective when predrilled, properly anchored, and sized to cover the full opening with correct edge support.

A side-by-side look clarifies trade-offs:

– Impact windows: always ready, daylight preserved, meaningful noise and UV reduction, higher upfront cost, low ongoing effort

– Panel shutters: lower initial cost, stacked storage, rapid deployment can be difficult, appearance changes at every install

– Accordion/roll-down: quick to close, semi-permanent tracks alter aesthetics, moving parts need periodic care

– Safety film: strengthens existing glass against shattering, but typically not rated for hurricane debris on its own

– Plywood: low material cost, heavy labor, limited lifespan, aesthetics suffer, code requirements for anchors may apply

When factoring total cost of ownership, include the time value of repeated deployment, potential travel during evacuation windows, and maintenance such as lubricating tracks or replacing corroded fasteners. For many households, windows provide a durable, integrated solution that supports both resilience and daily comfort. Others prefer a hybrid approach—impact units on the most exposed elevations and deployable protection elsewhere—to balance budget and performance.

A final consideration is habitability. During a prolonged event, closed shutters can darken interiors and trap heat, complicating life if power is lost. Impact glazing keeps rooms usable and supports ventilation when safe to crack an operable sash on the lee side after the storm weakens. The goal is not simply to protect glass, but to preserve a home you can return to without extensive cleanup and days of interruption.

From Quote to Long-Term Care: Buying Guide, Installation, and Conclusion

A smart purchase starts with a site-specific assessment. Ask a qualified professional to verify your mapped wind speed, exposure, and opening sizes, then calculate design pressures for each orientation. Request products with documented impact and cyclic pressure ratings that meet or exceed those demands. In coastal regions, many jurisdictions maintain product approval databases—make sure your selection appears with current documentation. Compare frame materials, glazing options, and hardware for corrosion resistance, and check warranty terms for both product and installation. Get multiple quotes that detail unit sizes, performance ratings, installation scope, flashing methods, and sealants so you can make clean comparisons.

Installation quality is as important as the window itself. Frames should be anchored into the structural framing, not just sheathing, using approved fasteners at specified spacing. Sill pans or equivalent flashing should manage incidental water, and joints should be sealed with compatible products that allow for thermal movement. Inspectors will look for proper edge cover over the glass, correct shimming, and intact drainage paths. After installation, test operable units for smooth action and confirm locks engage fully. Keep a record of labels, approvals, and pressure ratings; take photos of the installation before trim covers everything. Simple maintenance goes a long way:

– Rinse frames and tracks with fresh water after salty spray events

– Lubricate hinges and locks with non-staining products

– Inspect sealants and weeps annually and renew as needed

– Clean glass with non-abrasive tools to avoid scratching coatings

With care, impact-resistant windows can deliver decades of service in harsh environments.

Financially, consider long-term returns. Some insurers offer credits for documented opening protection; energy-efficient glazing can reduce cooling demand; and resale markets often value a home that is storm-ready. While savings vary by region and product, many owners cite reduced stress as the most meaningful return. Conclusion: Homeowners in wind-prone regions need solutions that protect the building envelope and simplify storm preparation. Impact-resistant hurricane windows stand out because they provide continuous, passive protection without sacrificing daylight or architectural character. If you prioritize year-round comfort, lower maintenance, and reliable resilience when forecasts turn ominous, this upgrade offers a clear, well-rounded path to a safer, quieter, and more livable home.