Understanding the Windshield Replacement Process and Costs

Outline and Why Windshield Replacement Matters Now

Every commute begins with a view, and the windshield is the quiet hero that frames it. It shields you from windblown debris, supports critical safety systems, and, when properly bonded, helps the vehicle keep its shape in a crash. When damage appears, many drivers postpone action, hoping a small star won’t spread. Yet glass behaves like a living material: temperature swings, body flex, and road vibrations can turn a pinprick into a creeping crack. This article gives you a clear path from concern to confident resolution, so you can protect visibility, safety, and your budget.

Here’s the roadmap we will follow, with each part expanded in the sections that follow:

– The role of the windshield in visibility, structure, and crash performance, including how laminated construction and coatings make a difference.

– Auto glass materials and features, from tempered versus laminated to acoustic interlayers, solar control, and camera brackets.

– The replacement process step-by-step, including adhesives, curing, weather constraints, and modern calibration needs.

– Costs, insurance, scheduling, and warranty considerations that influence real-world decisions.

– A practical conclusion and decision framework tailored to everyday drivers, families, and fleet managers.

Why this matters now: modern vehicles rely on the windshield more than ever. Many cars have forward-facing cameras or sensors mounted at the glass, and these devices often require calibration after replacement to ensure systems like lane keeping and automatic emergency braking function as intended. Industry figures commonly note that the bonded windshield can contribute meaningfully to a vehicle’s structural performance, particularly in rollovers and airbag deployment. While exact percentages vary by model, the takeaway is consistent: a correctly installed windshield isn’t cosmetic; it’s fundamental.

This guide balances clarity with detail. You’ll learn how to identify damage that can be repaired versus replaced, what materials influence comfort and fuel efficiency, and which installation steps separate careful craftsmanship from risky shortcuts. We’ll use plain language, note the variables that affect cost and timing, and offer practical checklists you can use when calling a shop. By the end, you will have a realistic understanding of options, trade-offs, and the steps to take today to keep your line of sight as clear as your plan.

Windshield: Structure, Safety, and Visibility

The windshield’s primary job—clear forward vision—seems obvious, but its deeper roles often go unnoticed. Windshields are typically made of laminated glass: two glass sheets bonded to a plastic interlayer. That interlayer keeps shards in place during impact, which helps maintain visibility and reduces ejection risk. It also damps noise, filters ultraviolet radiation, and can be engineered to manage solar heat, reducing cabin load on hot days. Some windshields include specialized layers that work with head-up display units or reduce acoustic harshness on highways, turning tough commutes into quieter, less fatiguing drives.

Safety is where the windshield earns its place as a structural component. The bond between glass and body—created by a high-strength automotive urethane—helps the car resist twisting and absorbs energy during collisions. Frequently cited industry data indicate that the windshield can contribute a substantial share of roof-crush resistance in specific designs, and it provides a backstop for passenger-side airbag deployment. While the exact degree varies, the message is consistent across vehicle types: proper bonding and glass quality matter for crash performance.

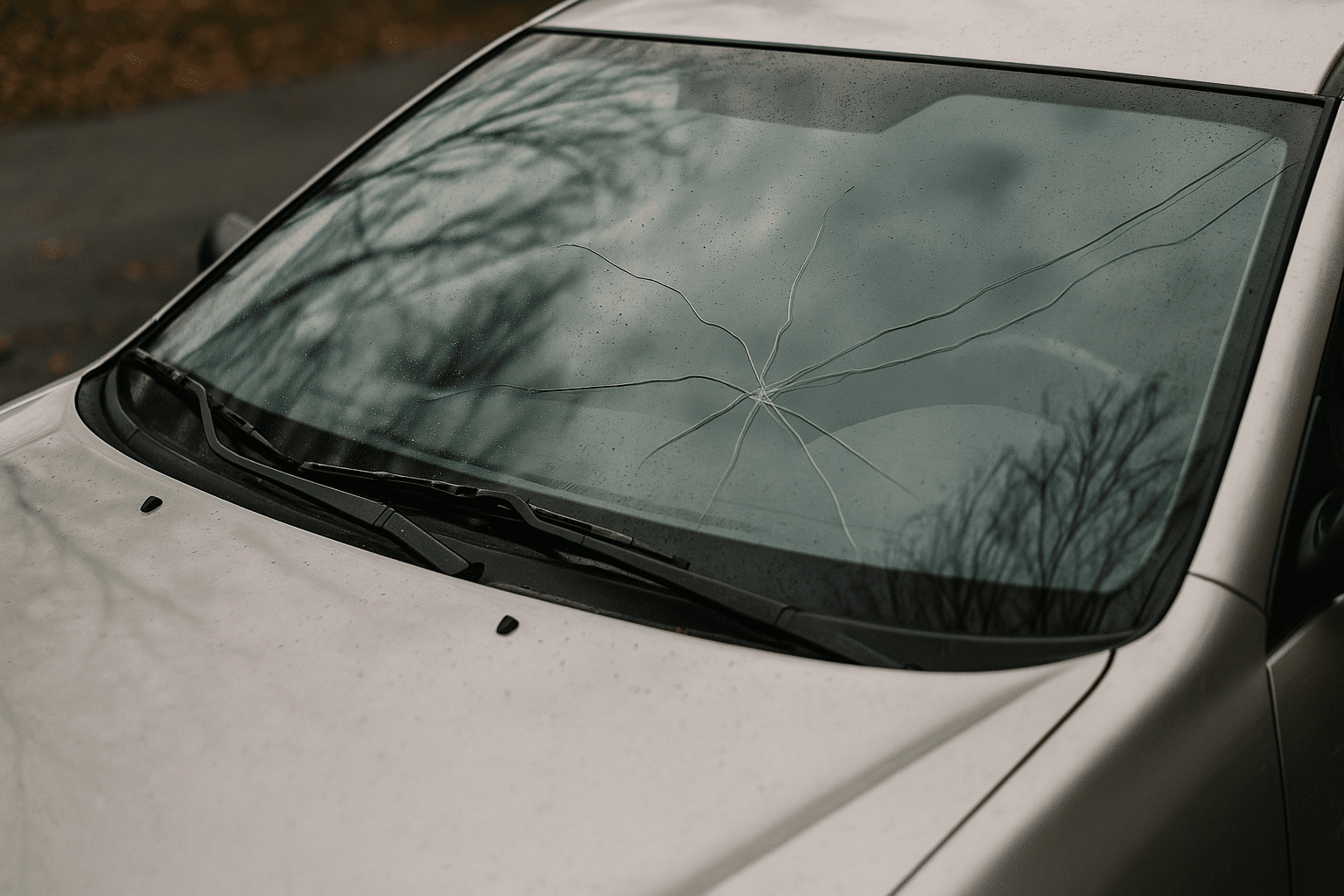

Damage assessment is the first decision point. Common patterns include:

– Bull’s-eye: circular damage from a rock, often repairable if small and shallow.

– Star break: radiating cracks that may spread with vibration or temperature changes.

– Combination break: mixed patterns that can be borderline cases.

– Edge crack: often higher risk because stress concentrates near the bond line.

In general, small chips and short cracks can be stabilized with professional resin injection, preserving the original factory bond and saving time. Factors that tilt the scale toward replacement include cracks extending into the driver’s primary sight zone, damage near edges, multiple fractures, or contamination that keeps repair resin from bonding. Another modern factor is the presence of sensors and cameras attached to the glass. If the mounting area is compromised or the inner surface is damaged, replacement becomes a more reliable path to restoring full functionality.

Visibility also involves optics. Quality windshields aim to minimize optical distortion—waves or “ripples” that can cause eye strain. The dark border printed around the edge (the frit) protects adhesive from ultraviolet light and hides the adhesive bead for a clean interior view. These details sound subtle, but they add up to safer night driving, clearer rain performance, and less fatigue. When you think of the windshield, think beyond the pane; think of it as a tuned lens, structural brace, and weather shield in one.

Auto Glass Materials and Features Explained

Auto glass falls into two broad families: laminated and tempered. The windshield is nearly always laminated—two plies of glass with a flexible interlayer—because the interlayer retains fragments and keeps the opening covered after impact. Side windows and the rear window are commonly tempered; this glass is heated and rapidly cooled to create surface compression, making it stronger than ordinary glass. When it breaks, it shatters into small, blunt-edged pieces that are less likely to cut. Some rear windows incorporate defogging elements, turning the glass into a functional heater during cold mornings.

Modern laminated windshields can include specialized interlayers to enhance comfort and performance:

– Acoustic interlayers help block traffic drone and wind roar.

– Solar-control interlayers or coatings reflect infrared energy, easing air-conditioning load.

– Tinted shade bands at the top reduce glare without overly dimming the road ahead.

Compatibility with advanced driver systems is another layer of complexity. Many windshields include a camera bracket, rain/light sensor area, or an engineered “wedge” for head-up display clarity. A mismatch in the optical characteristics near the camera can degrade system performance, which is why replacing like-for-like specifications matters. You might also see markings such as AS1 on the glass, indicating compliance with applicable safety glazing standards and helping identify the correct part when ordering.

Optical quality affects comfort. Slight variations in curvature or thickness can introduce distortion, especially noticeable in peripheral vision or when scanning reflective road signs at night. Well-regarded glass suppliers aim to keep distortion within tight tolerances, and installers look for subtle defects before installation: scratches along the edges, chips near mounting points, or wavy reflections that can cause eye strain. Paying attention to these details helps avoid noise issues too, since microgaps at the perimeter can create whistles at highway speed.

Finally, consider durability in real-world conditions. A windshield’s outer layer faces sand, salt, bugs, and micro-impacts that create pitting over time. Pitting scatters light and can make night driving feel like looking through haze. While no windshield is immune, choosing glass with the correct spec for your vehicle, ensuring proper adhesive use, and maintaining wipers can meaningfully extend clarity. If your vehicle sees frequent gravel roads or winter treatment, inspections every oil-change interval can catch early damage before it becomes a line across your field of view.

Replacement Process, Calibration, and Quality Control

Replacing a windshield is more than lifting out old glass and dropping in new. A careful process protects interior finishes, restores structural bonding, and sets you up for reliable performance in rain, heat, and sudden stops. It starts with a pre-inspection: technicians confirm the exact glass specification, note sensors and features, assess rust at the pinch weld (the metal frame lip), and photograph the existing damage. Removing the old glass involves cutting the cured urethane bead, lifting the panel without bending the body lip, and disposing of the glass safely.

Preparation is where quality differences become visible. The old adhesive is trimmed, leaving a thin, uniform layer that helps the new bead bond chemically—this “trim-and-bond” method is widely favored over scraping to bare metal. Any exposed metal is cleaned and primed; surface rust is treated so it doesn’t creep under the new bond line. The new glass is dry-fit to confirm alignment of brackets, mirror mount, and sensors. Adhesive choice matters: high-modulus, crash-tested automotive urethane with a documented safe drive-away time is used, and cure time depends on temperature and humidity. Shops track these variables to estimate when it’s safe to put the vehicle back on the road.

Modern vehicles often require calibration after replacement. Cameras behind the windshield may need a static calibration on a target board or a dynamic calibration performed while driving under specific conditions. The goal is simple: ensure lane lines, vehicles ahead, and traffic signs are recognized correctly. Skipping calibration can trigger warning lights or degrade assistance features, so it’s an essential part of the job when applicable. After calibration, technicians verify wiper sweep, sensor adhesion, and demist performance at the glass edge.

Quality control wraps the process:

– Alignment check: even gaps along the A-pillars and cowl, no glass sitting proud.

– Leak test: gentle water spray to detect any seeping at corners.

– Wind-noise test: short highway drive to listen for whistles or buffeting.

– Cleanliness: adhesive smears removed, dashboard and seats protected.

Weather and environment matter. Mobile replacement is convenient, but high humidity, dust, or very low temperatures can affect adhesive cure or contaminate bonding surfaces. In-shop service offers controlled conditions and easier access to calibration equipment. Either way, the principle stands: clean surfaces, correct primers, adhesive within its shelf life, and respect for cure times are what make the difference between a windshield that simply stays in place and one that performs as part of the vehicle’s safety system.

Costs, Insurance, and a Practical Decision Framework

Costs vary because vehicles and windshields vary. A basic laminated windshield without sensors can fall in a lower price range, while models with camera brackets, acoustic layers, solar coatings, or head-up display compatibility climb higher. Calibration adds a separate line item; depending on the vehicle and whether static, dynamic, or both are required, it can notably influence the final bill. Labor, rust remediation, moldings, and specialty primers also factor in. In general terms, many standard replacements land in mid-hundreds, while feature-rich windshields and calibration can push totals higher. Local market rates and availability further shape the final number.

Insurance can soften the impact. Comprehensive coverage often applies to glass damage, subject to a deductible. Some regions offer reduced or zero-deductible glass coverage, especially for windshields, recognizing their safety role. Filing a claim versus paying out-of-pocket depends on the deductible compared to the quote, potential impacts on premiums under your policy, and convenience. A few practical steps help:

– Get two or three itemized quotes that list glass specification, moldings, calibration, and any fees.

– Ask about safe drive-away time and whether calibration is included or subcontracted.

– Confirm warranty terms for both materials and workmanship, including leak and wind-noise coverage.

How do you decide between repair and replacement? Consider the size, location, and type of damage, how long it has been exposed, and whether the driver’s primary view is affected. Repairs are usually quicker and less expensive, and they preserve the factory bond. Replacement is favored when damage is near the edge, obscures sight lines, involves multiple cracks, or compromises sensor areas. Timing matters: addressing damage early can prevent propagation, keeping options open and costs lower.

As a concluding framework, think clarity, safety, and value—then act accordingly:

– Clarity: If you notice glare halos, nighttime starbursts, or spreading lines, schedule an evaluation.

– Safety: If the crack reaches the edge or intrudes on the camera zone, lean toward replacement and calibration.

– Value: Compare claim versus cash price, factor in downtime, and choose providers that follow recognized safety standards and document their process.

Whether you’re a daily commuter, a parent shuttling kids, or a fleet manager watching uptime, a well-chosen repair or replacement restores confidence every time you turn the key. Treat the windshield as part of your safety gear, plan the work with accurate specs and documented steps, and keep wipers, washer fluid, and tires in good shape to support clear vision. When the next pebble taps your glass, you’ll have more than a view—you’ll have a plan.